Wire Mesh

ACE ALLOYS LLP is renowned supplier & trader of high quality Steel Wire Mesh, which is available in various sizes and shapes. We also offer the same in different forms such as Stainless Steel Wire Mesh, Brass Alloy Wire Mesh, Copper Alloy Wire Mesh, Nickel Alloy Wire Mesh, Phosphor Bronze Wire Mesh, Black Wire Mesh, and Star Insect Screen.

This Hexagonal Wire Mesh offered by ACE ALLOYS is an electric fusion welded prefabricated joined grid consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. It is also used in mines, gardening, machine protection and other decorations.

This Welding Wire Mesh offered by ACE ALLOYS is widely used in agricultural, industrial, transportation, horticultural and food procuring sectors. The sizes are specified by combining the spacing, in inches or mm, and the wire cross section area in hundredths of square inches or mm.

Our Netting Wire Mesh is a square grid of uniformly placed wires, welded at all intersections, and meeting the requirements of ASTM or other standards. Machines are used to produce the mesh with precise dimensional control, where the product can result in considerable savings in time, labour and money.

Our range of Fencing Wire Mesh is designed and developed in conformation with set industrial standards and meet international quality norms. ACE ALLOYS also offer these in different sizes, shapes and designs as per customers’ specifications at affordable rates.

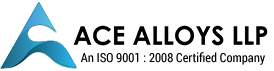

Stainless Steel Wire Mesh

Being a noteworthy enterprise of this industry, we Ace Alloys LLP. are Manufacturing & Exporting a wide spectrum of Stainless Steel Wire Mesh.

The Stainless Steel Wire Mesh we offer made by using high grade quality Stainless Steel thus known for their Corrosion resistant nature, Excellent finishing, High quality, Ability to withstand temperature variations, Heat-resistant, Reasonable price. These wire mesh are widely appreciated in industrial Apllications such as Machine Manufacturing units, Construction Secto, Filtration Applications, Oil & Chemical Industries, Pharma Industries,Food Industries

Specification for Stainless Steel Wire Mesh

| Mesh | SWG | DIAMETERS OF WIRE | SIZE OF OPENING | Approx Percentage Open Area | |||

|---|---|---|---|---|---|---|---|

| Inch | MM | Inch | MM | Micron | |||

| 4 | 12 | 0.104 | 2.640 | 0.146 | 3,710 | 3,710 | 34.14 |

| 4 | 13 | 0.092 | 2.340 | 0.158 | 4,010 | 4,010 | 39.98 |

| 4 | 14 | 0.080 | 2.030 | 0.170 | 4,320 | 4.320 | 46,28 |

| 4 | 15 | 0.072 | 1.830 | 0.178 | 4,520 | 4,520 | 50.67 |

| 4 | 16 | 0.064 | 1.630 | 0.186 | 4,720 | 4,720 | 55.25 |

| 4 | 17 | 0.056 | 1.430 | 0.194 | 4,920 | 4,920 | 60.03 |

| 4 | 18 | 0.048 | 1.220 | 0.202 | 5,130 | 5,130 | 65.27 |

| 5 | 14 | 0.080 | 2.030 | 0.120 | 3,050 | 3,050 | 36.05 |

| 5 | 15 | 0.072 | 1.830 | 0.128 | 3,250 | 3,250 | 40.93 |

| 5 | 16 | 0.064 | 1.630 | 0.136 | 3,450 | 3,450 | 46.12 |

| 5 | 17 | 0.056 | 1.430 | 0.144 | 3,650 | 3650 | 51.62 |

| 5 | 18 | 0.048 | 1.220 | 0.152 | 3,860 | 3,860 | 57.74 |

| 5 | 19 | 0.040 | 1.020 | 0.160 | 4,060 | 4,060 | 63.87 |

| 5 | 20 | 0.036 | 0.910 | 0.164 | 4,170 | 4,170 | 67.38 |

| 6 | 16 | 0.064 | 1.630 | 0.102 | 2,603 | 2,603 | 37.82 |

| 6 | 17 | 0.056 | 1.430 | 0.110 | 2,803 | 2,803 | 43.85 |

| 6 | 19 | 0.040 | 1.020 | 0.127 | 3,213 | 3,213 | 57.62 |

| 6 | 20 | 0.036 | 0.910 | 0.131 | 3,323 | 3,323 | 61.63 |

| 6 | 21 | 0.032 | 0.810 | 0.135 | 3,423 | 3,423 | 65.39 |

| 8 | 16 | 0.064 | 1.630 | 0.061 | 1,545 | 1545 | 23.68 |

| 8 | 17 | 0.056 | 1.430 | 0.061 | 1,745 | 1,745 | 30.21 |

| 8 | 18 | 0.048 | 1.220 | 0.077 | 1,955 | 1,955 | 37.91 |

| 8 | 19 | 0.040 | 1.020 | 0.085 | 2,155 | 2,155 | 46.07 |

| 8 | 20 | 0.036 | 0.910 | 0.089 | 2,265 | 2,265 | 50.89 |

| 8 | 21 | 0.032 | 0.810 | 0.093 | 2,365 | 2,365 | 55.48 |

| 8 | 22 | 0.028 | 0.710 | 0.097 | 2,465 | 2,465 | 60.28 |

| 8 | 23 | 0.024 | 0.610 | 0.0101 | 2,565 | 2,565 | 65.27 |

| 8 | 24 | 0.022 | 0.550 | 0.103 | 2,625 | 2,625 | 68.36 |

| 8 | 25 | 0.020 | 0.500 | 0.105 | 2,675 | 2,675 | 70.98 |

| 10 | 20 | 0.036 | 0.910 | 0.064 | 1,630 | 1,630 | 41.18 |

| 10 | 21 | 0.032 | 0.810 | 0.068 | 1,730 | 1,730 | 46.39 |

| 10 | 22 | 0.028 | 0.710 | 0.072 | 1,830 | 1,830 | 51.91 |

| 10 | 23 | 0.024 | 0.610 | 0.076 | 1,930 | 1,930 | 57.74 |

| 10 | 24 | 0.022 | 0.550 | 0.078 | 1,990 | 1,990 | 61.38 |

| 10 | 25 | 0.020 | 0.500 | 0.080 | 2,040 | 2,040 | 64.50 |

| 12 | 22 | 0.028 | 0.710 | 0.055 | 1,407 | 1,407 | 44.16 |

| 12 | 23 | 0.024 | 0.610 | 0.059 | 1,507 | 1,507 | 50.67 |

| 12 | 24 | 0.022 | 0.550 | 0.062 | 1,567 | 1,567 | 54.78 |

| 12 | 25 | 0.020 | 0.500 | 0.064 | 1,617 | 1,617 | 58.34 |

| 12 | 26 | 0.018 | 0.450 | 0.066 | 1,667 | 1,667 | 62.00 |

| 14 | 24 | 0.022 | 0.550 | 0.050 | 1,264 | 1,264 | 48.56 |

| 14 | 25 | 0.020 | 0.500 | 0.052 | 1,314 | 1,314 | 52.48 |

| 14 | 26 | 0.018 | 0.450 | 0.054 | 1,364 | 1,364 | 56.55 |

| 14 | 27 | 0.016 | 0.400 | 0.056 | 1,414 | 1,414 | 60.77 |

| 14 | 28 | 0.015 | 0.370 | 0.057 | 1,444 | 1,444 | 63.37 |

| 16 | 24 | 0.022 | 0.550 | 0.041 | 1,038 | 1,038 | 42.71 |

| 16 | 25 | 0.020 | 0.500 | 0.043 | 1,088 | 1,088 | 46.93 |

| 16 | 26 | 0.018 | 0.450 | 0.045 | 1,138 | 1,138 | 51.34 |

| 16 | 27 | 0.016 | 0.400 | 0.047 | 1,188 | 1,188 | 55.96 |

| 16 | 29 | 0.013 | 0.340 | 0.049 | 1,248 | 1,248 | 61.75 |

| 16 | 30 | 0.012 | 0.310 | 0.050 | 1,278 | 1,278 | 64.76 |

| 18 | 25 | 0.020 | 0.500 | 0.036 | 0.911 | 911 | 41.69 |

| 18 | 26 | 0.018 | 0.450 | 0.038 | 0.961 | 961 | 46.39 |

| 18 | 27 | 0.016 | 0.400 | 0.040 | 1.011 | 1,011 | 51.34 |

| 18 | 28 | 0.015 | 0.370 | 0.041 | 1.041 | 1,041 | 54.43 |

| 20 | 24 | 0.022 | 0.550 | 0.028 | 0.720 | 720 | 32.14 |

| 20 | 25 | 0.020 | 0.500 | 0.030 | 0.770 | 770 | 36.76 |

| 20 | 26 | 0.018 | 0.450 | 0.032 | 0.820 | 820 | 41.69 |

| 20 | 27 | 0.016 | 0.400 | 0.034 | 0.870 | 870 | 46.93 |

| 20 | 28 | 0.015 | 0.370 | 0.035 | 0.900 | 900 | 50.22 |

| 20 | 29 | 0.013 | 0.340 | 0.037 | 0.930 | 930 | 53.62 |

| 20 | 30 | 0.012 | 0.310 | 0.038 | 0.960 | 960 | 57.14 |

| 24 | 27 | 0.016 | 0.400 | 0.026 | 0.658 | 658 | 38.69 |

| 24 | 28 | 0.015 | 0.370 | 0.027 | 0.688 | 688 | 42.30 |

| 24 | 29 | 0.013 | 0.340 | 0.028 | 0.718 | 718 | 46.07 |

| 24 | 30 | 0.012 | 0.310 | 0.029 | 0.748 | 748 | 50.00 |

| 24 | 32 | 0.011 | 0.270 | 0.031 | 0.788 | 788 | 55.48 |

| 30 | 28 | 0.015 | 0.370 | 0.019 | 0.477 | 477 | 31.70 |

| 30 | 29 | 0.013 | 0.340 | 0.020 | 0.507 | 507 | 35.81 |

| 30 | 30 | 0.012 | 0.310 | 0.021 | 0.537 | 537 | 40.18 |

| 30 | 31 | 0.011 | 0.290 | 0.022 | 0.557 | 557 | 43.23 |

| 30 | 32 | 0.011 | 0.270 | 0.023 | 0.557 | 577 | 46.39 |

| 40 | 32 | 0.011 | 0.270 | 0.014 | 0.365 | 365 | 33.04 |

| 40 | 33 | 0.010 | 0.250 | 0.015 | 0.385 | 385 | 36.76 |

| 40 | 34 | 0.009 | 0.234 | 0.016 | 0.401 | 401 | 39.88 |

| 40 | 35 | 0.008 | 0.210 | 0.017 | 0.425 | 425 | 44.80 |

| 40 | 36 | 0.008 | 0.193 | 0.017 | 0.442 | 442 | 48.45 |

| 50 | 34 | 0.009 | 0.234 | 0.011 | 0.274 | 274 | 29.09 |

| 50 | 35 | 0.008 | 0.210 | 0.012 | 0.298 | 298 | 34.41 |

| 50 | 36 | 0.008 | 0.193 | 0.012 | 0.315 | 315 | 38.45 |

| 50 | 37 | 0.007 | 0.172 | 0.013 | 0.336 | 336 | 43.75 |

| 50 | 38 | 0.006 | 0.152 | 0.014 | 0.356 | 356 | 49.11 |

| 60 | 36 | 0.008 | 0.193 | 0.009 | 0.230 | 230 | 29.60 |

| 60 | 37 | 0.007 | 0.172 | 0.010 | 0.251 | 251 | 32.25 |

| 60 | 38 | 0.006 | 0.152 | 0.011 | 0.271 | 271 | 41.08 |

| 80 | 38 | 0.006 | 0.152 | 0.007 | 0.166 | 166 | 21.17 |

| 80 | 39 | 0.005 | 0.130 | 0.007 | 0.188 | 188 | 34.88 |

| 80 | 40 | 0.005 | 0.122 | 0.008 | 0.196 | 196 | 37.91 |

| 80 | 41 | 0.004 | 0.112 | 0.008 | 0.206 | 206 | 41.89 |

| 80 | 42 | 0.004 | 0.102 | 0.008 | 0.216 | 216 | 46.07 |

| 100 | 42 | 0.004 | 0.102 | 0.006 | 0.152 | 152 | 35.81 |

| 100 | 43 | 0.004 | 0.091 | 0.006 | 0.163 | 163 | 41.18 |

| 100 | 44 | 0.003 | 0.081 | 0.007 | 0.173 | 173 | 46.39 |

| 120 | 44 | 0.003 | 0.081 | 0.005 | 0.131 | 131 | 38.11 |

| 150 | 45 | 0.003 | 0.071 | 0.004 | 0.098 | 98 | 33.72 |

| 150 | 45.5 | 0.002 | 0.063 | 0.004 | 0.106 | 106 | 39.43 |

| 200 | 47 | 0.002 | 0.050 | 0.003 | 0.077 | 77 | 36.76 |

| 250 | 48 | 0.002 | 0.040 | 0.002 | 0.062 | 62 | 36.76 |

| 300 | 48 | 0.002 | 0.040 | 0.002 | 0.045 | 45 | 27.83 |

| 325 | 48.5 | 0.001 | 0.035 | 0.002 | 0.043 | 43 | 30.49 |

| 400 | 49.5 | 0.001 | 0.028 | 0.001 | 0.036 | 36 | 31.25 |

| 500 | 50 | 0.001 | 0.025 | 0.001 | 0.026 | 26 | 25.79 |

| WEAVE TYPE | MESH COUNT | WARP WIRE IN INCHES | SHUTE WIRE IN INCHES | ABSOLUTE MICRON RATING | NOMINAL MICRON RATING | |

|---|---|---|---|---|---|---|

| PDW | 8X20 | 0.014 | 0.0126 | 330-350 | 280 | |

| PDW | 12X64 | 0.024 | 0.0165 | 270-290 | 200 | |

| PDW | 14X88 | 0.02 | 0.013 | 220-240 | 150 | |

| PDW | 16X80 | 0.0169 | 0.0134 | 225-235 | 140 | |

| PDW | 24X110 | 0.015 | 0.01 | 115-125 | 80 | |

| PDW - TWIN WARP | 24X128 | 2 X .010 | 0.004 | 110-120 | 75 | |

| PDW | 30X150 | 0.009 | 0.007 | 110-112 | 63 | |

| PDW - TWIN WARP | 30X150 | 2 X .009 | .007" | 95-113 | 60 | |

| PDW | 40X200 | 0.007 | 0.0055 | 70-75 | 55 | |

| PDW | 50X250 | 0.0055 | 0.0045 | 58-63 | 40 | |

| PDW | 80X400 | 0.005 | 0.003 | 40-45 | 35 | |

| TDW | 30X250 | 0.01 | 0.008 | 110-120 | 53 | |

| TDW | 80X700 | 0.004 | 0.003 | 35-40 | 25 | |

| TDW | 120X400 | 0.004 | 0.0025 | 50-55 | 40 | |

| TDW | 165X800 | 0.0028 | 0.002 | 25-28 | 15 | |

| TDW | 200X600 | 0.0024 | 0.0018 | 30 | 20 | |

| TDW | 165X1400 | 0.0028 | 0.0016 | 16-20 | 10 | |

| TDW | 200X1400 | 0.0028 | 0.0016 | 12-14 | 5 | |

| TDW | 325X2300 | 0.0014 | 0.001 | 8-9 | 2 | |

| TDW | 400X2800 | 0.001 | 0.0008 | 6-7 | 1 |

| Grade | C Max |

Mn Max |

P Max |

S Max |

Si Max |

Cr Min/Max |

Ni Max |

MO Max |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 18-20 | 18-10 | - |

| 304L | 0.03 | 2.00 | 0.05 | 0.03 | 1.00 | 16-18 | 18-12 | - |

| 316 | 0.08 | 2.00 | 0.05 | 0.03 | 1.00 | 16-18 | 10-14 | 2-2.25 |

| 316L | 0.03 | 2.00 | 0.05 | 0.03 | 1.00 | 16-18 | 10-14 | 2-2.25 |

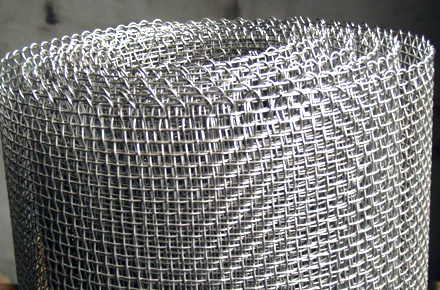

Brass Alloy Wire Mesh

With our expertise in this domain, we Ace Alloy llp. are able to manufacture & Export a superior quality range of Brass Wire Mesh. All our products are available in various sizes, designs, and shapes at market leading prices to meet the demands of customers.

Our range of Brass Wire Mesh has gained appreciation from the clients due to its abrasion & corrosion resistance, higher strength and lower electrical conductivity. These are widely used for sieving various pellet, porcelain clay & glass, powder, chinaware printing, filtering liquid and gas.

Specification for Brass Alloy Wire Mesh

| Mesh | Wire Dia.(mm) | Opening(mm) | ||

|---|---|---|---|---|

| SWG | MM | Inch | ||

| 6 | 22 | 0.711 | 0.028 | 3.522 |

| 8 | 23 | 0.610 | 0.024 | 2.565 |

| 10 | 25 | 0.508 | 0.020 | 2.032 |

| 12 | 26 | 0.457 | 0.018 | 1.660 |

| 14 | 27 | 0.417 | 0.016 | 1.397 |

| 16 | 29 | 0.345 | 0.014 | 1.243 |

| 18 | 30 | 0.315 | 0.012 | 1.096 |

| 20 | 30 | 0.315 | 0.0124 | 0.955 |

| 22 | 30 | 0.315 | 0.0124 | 0.840 |

| 24 | 0 | 0.315 | 0.0124 | 0.743 |

| 26 | 31 | 0.295 | 0.0116 | 0.682 |

| 28 | 31 | 0.295 | 0.0116 | 0.612 |

| 30 | 32 | 0.247 | 0.011 | 0.573 |

| 32 | 33 | 0.254 | 0.010 | 0.540 |

| 34 | 34 | 0.234 | 0.0092 | 0.513 |

| 36 | 34 | 0.234 | 0.0092 | 0.472 |

| 38 | 35 | 0.213 | 0.0084 | 0.455 |

| 40 | 36 | 0.193 | 0.0076 | 0.442 |

| 42 | 36 | 0.193 | 0.0076 | 0.412 |

| 44 | 37 | 0.173 | 0.0068 | 0.404 |

| 46 | 37 | 0.173 | 0.0068 | 0.404 |

| 48 | 37 | 0.173 | 0.0068 | 0.356 |

| 50 | 37 | 0.173 | 0.0068 | 0.335 |

| 60x50 | 36 | 0.193 | 0.0076 | |

| 60x50 | 37 | 0.173 | 0.0068 | |

| 60 | 37 | 0.173 | 0.0068 | 0.250 |

| 70 | 39 | 0.132 | 0.0052 | 0.231 |

| 80 | 40 | 0.122 | 0.0048 | 0.196 |

| 90 | 41 | 0.112 | 0.0044 | 0.170 |

| 100 | 42 | 0.102 | 0.004 | 0.152 |

| 120x108 | 43 | 0.091 | 0.0036 | |

| 120 | 44 | 0.081 | 0.0032 | 0.131 |

| 140 | 46 | 0.061 | 0.0024 | 0.120 |

| 150 | 46 | 0.061 | 0.0024 | 0.108 |

| 160 | 46 | 0.061 | 0.0024 | 0.098 |

| 180 | 47 | 0.051 | 0.002 | 0.090 |

| 200 | 47 | 0.051 | 0.002 | 0.076 |

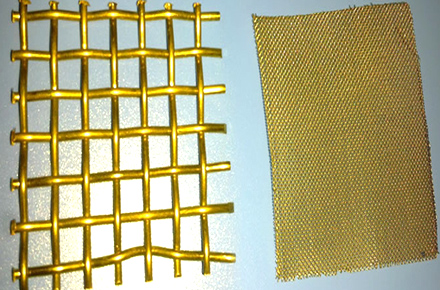

Copper Alloy Wire Mesh

We Ace Alloy llp. is a distinguished manufacturer, exporter and supplier of a wide assortment of Copper Alloy Wire Mesh. The offered mesh is broadly used for commercial and non-commercial applications.

Our range is widely acclaimed by our clients for its characteristic features such as durability, corrosion resistance and high tensile strength, Electromagnetic and thermal conduction properties, Resistant to atmospheric corrosion, Anti sparkling, Darkens after a period of time.

Specification for Copper Alloy Wire Mesh

| Opening/linear inch | Wire Diameter | Width of Opening | Open Area | ||

|---|---|---|---|---|---|

| Inches | mm | Inches | mm | ||

| 2 Mesh | 0.063 | 1.60 | 0.437 | 11.10 | 76.4% |

| 4 Mesh | 0.047 | 1.19 | 0.203 | 5.16 | 65.9% |

| 4 Mesh | 0.063 | 1.60 | 0.187 | 4.75 | 55.9% |

| 8 Mesh | 0.028 | 0.71 | 0.097 | 2.46 | 60.2% |

| 10 Mesh | 0.025 | 0.64 | 0.075 | 1.91 | 56.3% |

| 12 Mesh | 0.023 | 0.584 | 0.060 | 1.52 | 52.4% |

| 14 Mesh | 0.020 | 0.508 | 0.051 | 1.30 | 51.8% |

| 16 Mesh | 0.011 | 0.279 | 0.0515 | 1.30 | 67.9% |

| 16 Mesh | 0.018 | 0.457 | 0.0445 | 1.13 | 50.7% |

| 18 Mesh | 0.017 | 0.432 | 0.0386 | 0.98 | 48.2% |

| 20 Mesh | 0.016 | 0.406 | 0.0340 | 0.86 | 46.2% |

| 24 Mesh | 0.014 | 0.356 | 0.0277 | 0.70 | 44.1% |

| 30 Mesh | 0.013 | 0.330 | 0.0203 | 0.52 | 37.2% |

| 40 Mesh | 0.010 | 0.254 | 0.0150 | 0.38 | 36.0% |

| 50 Mesh | 0.009 | 0.229 | 0.0110 | 0.28 | 30.3% |

| 60 Mesh | 0.0075 | 0.191 | 0.0092 | 0.23 | 30.2% |

| 80 Mesh | 0.0055 | 0.140 | 0.0070 | 0.18 | 31.4% |

| 100 Mesh | 0.0045 | 0.114 | 0.0055 | 0.14 | 30.3% |

| 100 Mesh | 0.0022 | 0.055 | 0.0078 | 0.198 | 60.8% |

| 145 Mesh | 0.0022 | 0.055 | 0.00469 | 0.1168 | 46.4% |

Nickel Alloy Wire Mesh

With genuine intentions to enhance our reputation in the national & international market, we Ace Alloys llp. Manufacturer & export an exceptional quality wide range of Nickel Wire Mesh. The wire mesh which we offer is widely valued for their long lasting service and wide uses.

Nickel 200/201 Wire Mesh is technically pure nickel with good mechanical properties and excellent resistance to alkali hydroxides as well as organic compositions. Nickel 200/201 Wire Mesh is a multipurpose grade and is used in application where alloys are not essential. It also has good magnetic and magnetostrictive properties, high thermal and electrical conductivity as well as low gas content in the electronics industry.

Phosphor Bronze Wire Mesh

We Ace Alloys llp. have gained expertise in manufacturing & exporting a supreme quality of Phosphor Bronze Wire Mesh. Our range has gained appreciation from the clients due to its abrasion & corrosion resistance, higher strength and lower electrical conductivity.

The wire mesh manufactured and supplied to our customer is thoroughly checked and tested. we take into consideration every minute detail while manufacturing these wire meshes, whether it is uniform mesh counting or uniform wire thickness or strength of the wire mesh.

Specification For Phosphor Bronze Alloy Wire Mesh

| mesh | wire diameter | opening (mm) | ||

|---|---|---|---|---|

| SWG | mm | inch | ||

| 6 | 22 | 0.711 | 0.028 | 3.522 |

| 8 | 23 | 0.610 | 0.024 | 2.565 |

| 10 | 25 | 0.508 | 0.020 | 2.032 |

| 12 | 26 | 0.457 | 0.018 | 1.660 |

| 14 | 27 | 0.417 | 0.016 | 1.397 |

| 16 | 29 | 0.345 | 0.014 | 1.243 |

| 18 | 30 | 0.315 | 0.012 | 1.096 |

| 20 | 30 | 0.315 | 0.0124 | 0.955 |

| 22 | 30 | 0.315 | 0.0124 | 0.840 |

| 24 | 30 | 0.315 | 0.0124 | 0.743 |

| 26 | 31 | 0.295 | 0.0116 | 0.682 |

| 28 | 31 | 0.295 | 0.0116 | 0.612 |

| 30 | 32 | 0.247 | 0.011 | 0.573 |

| 32 | 33 | 0.254 | 0.010 | 0.540 |

| 34 | 34 | 0.234 | 0.0092 | 0.513 |

| 36 | 34 | 0.234 | 0.0092 | 0.472 |

| 38 | 35 | 0.213 | 0.0084 | 0.455 |

| 40 | 36 | 0.193 | 0.0076 | 0.442 |

| 42 | 36 | 0.193 | 0.0076 | 0.412 |

| 44 | 37 | 0.173 | 0.0068 | 0.404 |

| 46 | 37 | 0.173 | 0.0068 | 0.379 |

| 48 | 37 | 0.173 | 0.0068 | 0.356 |

| 50 | 37 | 0.173 | 0.0068 | 0.335 |

| 60X50 | 36 | 0.0076 | 0.0076 | - |

| 60X50 | 37 | 0.0068 | 0.0068 | - |

| 60 | 37 | 0.0068 | 0.0068 | 0.250 |

| 70 | 39 | 0.132 | 0.0052 | 0.231 |

| 80 | 40 | 0.122 | 0.0048 | 0.196 |

| 90 | 41 | 0.112 | 0.0044 | 0.170 |

| 100 | 42 | 0.012 | 0.004 | 0.152 |

| 120X108 | 43 | 0.091 | 0.0036 | - |

| 120 | 44 | 0.081 | 0.3200 | 0.131 |

| 140 | 46 | 0.061 | 0.0024 | 0.120 |

| 150 | 46 | 0.061 | 0.0024 | 0.108 |

| 160 | 46 | 0.061 | 0.0024 | 0.098 |

| 180 | 47 | 0.051 | 0.002 | 0.090 |

| 200 | 47 | 0.051 | 0.002 | 0.076 |

| 250 | 48 | 0.041 | 0.0016 | 0.061 |

| 300 | 49 | 0.031 | 0.0012 | 0.054 |

| 325 | 49 | 0.031 | 0.0012 | 0.047 |

| 350 | 49 | 0.031 | 0.0012 | 0.042 |

| 400 | 49 | 0.031 | 0.0012 | 0.033 |

| 450 | 49 | 0.031 | 0.0012 | 0.029 |

| 500 | 50 | 0.025 | 0.0010 | 0.026 |

Black Wire Mesh

We Ace Alloys llp. involved in manufacturing & exporting a wide array of Black Wire Mesh to cater the variegated requirements of the customers worldwide. These Black Wire Mesh are manufactured using premium grade raw material that is specially tested before manufacturing the final assortment

These Black Wire Mesh are made from very high quality raw material which ensures high durability at its user end. These Black Wire Mesh are in high demand in the market. Different sizes and designs are easily available in the market.

Features

- Good strength

- Uniform mesh

- Fine rigidity

Specification for Black Wire Mesh

| Mesh | Wire Dia.( mm) | Opening (mm) |

|---|---|---|

| 8 | 0.71 | 2.47 |

| 10 | 0.65 | 1.89 |

| 12 | 0.60 | 1.52 |

| 14 | 0.50 | 1.31 |

| 16 | 0.40 | 1.19 |

| 20 | 0.40 | 0.87 |

| 24 | 0.35 | 0.71 |

| 30 | 0.30 | 0.55 |

| 40 | 0.25 | 0.39 |

| 50 | 0.20 | 0.31 |

| 60 | 0.17 | 0.25 |

| 80X70 | 0.135 | - |

| 100X90 | 0.11 | - |

Star Insect Screen

With firm commitment to quality, we Ace Alloys llp. are engaged in Manufacturing & Exporting a quality-assured array of Star Insect Screen. With state-of-the-art infrastructure facilities we procure these product by using optimum quality material.

Our offered ranges of Insect Screen is widely used to prevent insects from entering the home, used in hotel, restaurant, communal building and residential houses to prevent the common insects or birds. These have aesthetic appearance and are offered in different options of size, range and colors.

Features

- Light Weight

- Good corrosion resisting and Rust resisting

- Precisely designed

- High grade material

- Excellent finish

Size Specification for Star Insect Wire Mesh

| Mesh size | Grade | Guage |

|---|---|---|

| 13*28.5 | 202,304,316(S.S) | 0.33 |

| 16*23 | 202,304,316(S.S) | 0.71 |

| 16*34 | 202,304,316(S.S) | 0.22 |

| 14*30 | 202,304,316(S.S) | 0.29 |

| 16*30 | 202,304,316(S.S) | 0.30 |

| Star Insect Wire Cloth Dutch Weave | |

|---|---|

| Mesh | Wire Dia.(mm) |

| 12X64 | 0.58/0.64 |

| 14X88 | 0.50/0.33 |

| 24X110 | 0.36/0.25 |

| 30X150 | 0.23/0.18 |

| 40X200 | 0.18/0.13 |