How to Choose Right Valve for Your Upcoming Project

Choosing a right Valve type can be too frustrating. If you are looking for a new valve for your project, and can’t decide on the best type, you’ve come to the right place. Here, we provide a brief guide on choosing the right valve for your project, but first the question is, why use a valve?

The answer is that it is required for two purposes, for regulation and shut off. As professional Valve Suppliers, we offer Flow Control Valves in a variety of designs. Industrial Valves with just and on/off capability are called Shut off valves which stops the flow through them.

Let’s take a look at the different Types of Valves:

1. Ball Valve

Ball valves are the example of shut off valves. It has a ball or a spherical seating that prevents the flow. The ball has a hole in the middle so that when the switch is turned ‘on’, the fluid or the gas will flow through it. The ‘off’ position is exactly at 90 degrees from the ‘on’ position and when the handle is turned towards ‘off’ position the fluid hits the solid side of the ball and the flow is stopped.

2. Check Valve

A check valve is a one way valve that allows fluid or gasses to flow through it in only one direction. They are also known as Non return valve. There are two categories of check valve i.e. swing check valve and ball check valve.

A check valve is a one way valve that allows fluid or gasses to flow through it in only one direction. They are also known as Non return valve. There are two categories of check valve i.e. swing check valve and ball check valve.

Swing check valve uses a swinging function to process unidirectional flow. In case of a back pressure from the flow, the spring loaded disc is forced back to close, sopping any reverse flow. Therefore, they are classified under control valves as they control the direction of the flow.

Ball check valve uses a ball to stop the reverse flow pressure. When the fluid or the gas pass through it in the desired direction, they flow around the ball. But when the flow is reversed, it hits the concave side which pushes the valve shut. They produce a slight drop in the pressure because of the hindrance caused from the ball.

3. Globe Valve

Globe valve most common manual control valves used majorly in ships. They are designed to start, stop as well as regulate the flow. The differential pressure across the disc of the valve should not exceed 20 % of the upstream pressure or 200 psi whichever is minimum. The flow can be stopped by moving the disc against the flow. The multi-directional flow causes huge pressure drop.

Globe valve most common manual control valves used majorly in ships. They are designed to start, stop as well as regulate the flow. The differential pressure across the disc of the valve should not exceed 20 % of the upstream pressure or 200 psi whichever is minimum. The flow can be stopped by moving the disc against the flow. The multi-directional flow causes huge pressure drop.

4. Needle Valve

This is one other type of flow control valve that uses a fine needle or a pin to control the flow through it. Thus it helps in the precise control of the flow. In order to preserve the service life and the smooth functioning of these types of valves, it is very important to choose the needle valve made from the material that best suits your needs, be it stainless steel, brass or bronze.

This is one other type of flow control valve that uses a fine needle or a pin to control the flow through it. Thus it helps in the precise control of the flow. In order to preserve the service life and the smooth functioning of these types of valves, it is very important to choose the needle valve made from the material that best suits your needs, be it stainless steel, brass or bronze.

A butterfly valve makes use of a rotating disc to regulate the flow. This disc is attached to a stem through a middle or offset, and when the valve is opened, the disc aligns with the flow and creates and unrestricted path for the flow. When turned 90 degrees to ‘off’ position’, it results quick shut off. This closing mechanism is usually the reason why they are known as quarter turn valves.

A butterfly valve makes use of a rotating disc to regulate the flow. This disc is attached to a stem through a middle or offset, and when the valve is opened, the disc aligns with the flow and creates and unrestricted path for the flow. When turned 90 degrees to ‘off’ position’, it results quick shut off. This closing mechanism is usually the reason why they are known as quarter turn valves.

They are used to break the product flow in pharmaceutical, petroleum and chemical industries due to the interruption requirement of the flow in these industries. The major advantages include lower cost and ease of installation and the major disadvantage is that it is very difficult to clean a butterfly valve.

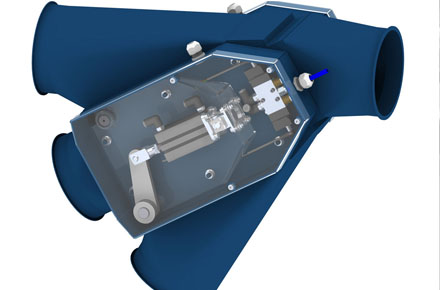

6. Diverter Valve

These valves direct the flow of a liquid or gas and are mainly used in automobile engines as well as bathroom showers. The general application temperature range is 100 degree for powders and granular products.

These valves direct the flow of a liquid or gas and are mainly used in automobile engines as well as bathroom showers. The general application temperature range is 100 degree for powders and granular products.

7. Safety Valve  A safety valve is a valve that acts as a fail-safe. The example is a Pressure Reducing Valve, which automatically releases pressure or other products, when the pressure or temperature exceeds a certain limit. The inlet valve disc opens when the pressure increases beyond a datum and closes when the pressure reduces.

A safety valve is a valve that acts as a fail-safe. The example is a Pressure Reducing Valve, which automatically releases pressure or other products, when the pressure or temperature exceeds a certain limit. The inlet valve disc opens when the pressure increases beyond a datum and closes when the pressure reduces.

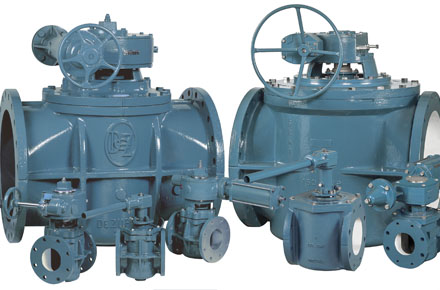

8. Plug Valve

They consists of a cylindrical plug with one or more holes which act as passageways so that the fluids/gas can pass through them. They are one of the widely used control valves. Plugs can be rotated by 90degrees to open or close.

They consists of a cylindrical plug with one or more holes which act as passageways so that the fluids/gas can pass through them. They are one of the widely used control valves. Plugs can be rotated by 90degrees to open or close.

9. Air Valve

They are used in pipelines for 2 purposes. The first is to release the air accumulated in a pressurised pipeline. The second function is to pass the air into the pipeline when the internal pressure reduces\falls below the atmospheric pressure. They are mainly used for agricultural projects.

As a leading valve manufacturer, we offer a wide range of valves for selection which are in compliance with all the necessary industrial standards. Contact us for all your valve requirements.